Roland Leatherwood and Neil S. Mattson

Cornell University

Ethylene, a small colorless, odorless gas composed of two carbon and four hydrogen atoms (C2H4), is responsible for both beneficial and undesirable effects in greenhouse crops. It can prevent flowering, shorten internode length, increase branching, initiate fruit ripening, trigger leaf and flower senescence and abscission, cause leaf chlorosis (yellowing), and improve adventitious rooting. Some crops are relatively insensitive to ethylene while others are very sensitive. For example, Poinsettia shows little change after a 24 hour 1 ppm ethylene exposure, yet Cuphea hyssopifolia abscises all flowers after a 24 hour 0.01 ppm exposure. There are many potential sources of unwanted ethylene such as ripening fruit, decomposing organic matter, and exhaust from furnaces and vehicles. Because several factors can simultaneously impact a plant’s response to ethylene, it is easy to see why assessing a potential ethylene problem can be tricky. Some symptoms of exposure can be transient, while others show up long after the ethylene exposure has occurred, still other responses show up only after long-term exposure. To help you eliminate ethylene related crop delays and losses from your operation, this webpage details what short term and chronic low concentration ethylene exposure looks like, how to detect ethylene, track down the source, and fix the problem.

What does ethylene damage look like?

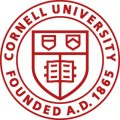

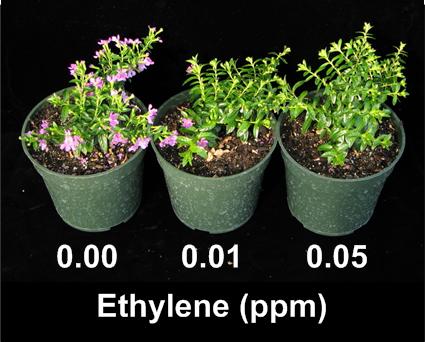

A plant’s response to ethylene can vary with temperature, ethylene concentration and duration of exposure. Plant responses to acute or high concentration (> 0.1 ppm), exposures are well described and studied. Many growers can readily identify these symptoms. Brief exposures may occur due to events such as shipping plants in a tightly sealed container or one-time exposure to vehicle exhaust while plants are in a loading zone. Short duration exposures at high concentrations result in flower and leaf abscission, chlorosis, and downward bent leaves that look wilted, but are turgid (epinasty) (Figure 1). Longer-term exposure to high concentrations of ethylene can result in stunted growth, deformed or chlorotic leaves, delayed flowering and plant death (senescence).

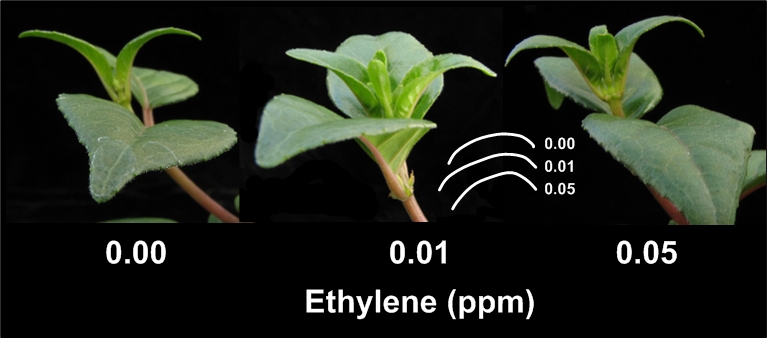

However, it can be more difficult to recognize plant responses to low concentration (< 0.05 ppm) exposures. Low concentration exposure to ethylene over extended periods of time (referred to as chronic ethylene exposure) can occur during greenhouse production such as when a furnace is malfunctioning and generates ethylene inside the greenhouse. To develop a visual diagnostic guide of chronic ethylene exposure, an experiment was conducted at Cornell University. Thirty species of bedding and potted plants were grown in separate greenhouses and were exposed to ethylene concentrations of 0.00, 0.01 and 0.05 ppm ethylene every night for the last 6 weeks of production. Some results of these experiments are presented below.

For many plant species responses to low concentration ethylene exposures are subtle and can be easily missed. For example, petunias exposed to 0.01 ppm ethylene for 24 hours, exhibit early senescence of pollen shedding flowers (Figure 2). Of course, as a grower you’re not tracking the life span of individual flowers, but the effect in the greenhouse would be a noticeable and sudden loss of petunia flowers in one part of the greenhouse, typically close to a furnace. Similarly zonal geraniums exhibit stipule yellowing after 48 hours when exposed to 0.01 ppm ethylene for 24 hours (Figure 4), yet the flowers do not shatter as is seen at higher concentrations. Longer term exposures at these concentrations result in less flowering for begonia, impatiens and lobelia (Figure 7), and petunia internode elongation and flower size is reduced (Figure 2). The figures below illustrate plant responses to low concentrations of ethylene. Complete results are summarized in Table 1.

| Table 1: Complete listing of all species tested and their response to short term and long term ethylene exposure. If the response appears at only a specific concentration, that will appear in the description. | ||

| Plant | Short Term Response

(After 72 hours) |

Long Term Response

(After Several Weeks) |

| Bacopa ‘Calypso Jumbo Lavender’ | Slight leaf curling | Reduced overall growth, flower counts and branching |

| Basil ‘Sweet Large Leaf’ | No Change (N/C) | Increased branching |

| Begonia fibrous ‘Cocktail Gin’ | N/C | Reduced height, overall growth, flower count |

| Calendula ‘Bon Bon Yellow’ | N/C | Reduced height, overall growth |

| Calibrachoa ‘Callie Dark Blue’ | N/C | Reduced height and overall growth, increased branching |

| Coleus ‘Stained Glassworks Copper’ | N/C | Increased branching |

| Cuphea ‘Allyson Heather’ | Complete flower shattering after 24 hours at 0.01 and 0.05 ppm ethylene | Reduced flowering, increased branching |

| Dahlia ‘Carolina Orange’ | N/C | Early flower senescence |

| Dianthus ‘Telstar Pink’ | N/C | Reduced height, branching, overall growth and flower counts |

| Fuchsia ‘Trailing Dark Eyes’ | Slight leaf curling which increases with concentration | Reduced branching, overall growth, increased height, flower counts |

| Zonal Geranium ‘Rumba Fire’ | Yellowing of stipules after 48 hours at 0.01 and 0.05 ppm ethylene | Increased flower counts |

| Gerbera ‘Jaguar Formula Mix’ | N/C | Leaves are flatter against the soil |

| Impatiens ‘Super Elfin XP White’ | Slight leaf curling after 24 hours at 0.05 ppm ethylene | Reduced height, overall growth, flower size and flower counts |

| Lobelia ‘Riviera Blue Splash’ | N/C | Reduced height, overall growth and flower counts |

| French Marigold ‘Crested Bonanza Mix’ | N/C | N/C |

| New Guinea Impatiens ‘Sonic Deep Purple’ | N/C | Reduced height, overall growth |

| Osteospermum ‘Asti Purple’ | N/C | Reduced overall growth, increased branching |

| Pansy ‘Delta Formula Mix’ | N/C | Reduced height |

| Hot Pepper ‘Long Red Thin Cayenne’ | N/C | N/C |

| Petunia multiflora prostrate single ‘Saguna Pastel Yellow’ | Rapid senescence of open flowers 24 to 48 hours after exposure to 0.01 and 0.05 ppm ethylene | Reduced overall growth, flower size and flower counts, increased height and branching |

| Portulaca ‘Yubi Summer Joy Apricot’ | Some leaf abscission within 24 hours of exposure to 0.05 ppm ethylene. Leaf abscission does not persist long term | Reduced height and increased branching. |

| Primula ‘Danova Select Mix’ | N/C | Leaves are flatter against the soil |

| Rosemary ‘Arp’ | N/C | Reduced branching |

| Sanvitalia ‘Sundance Yellow’ | N/C | N/C |

| Snapdragon ‘Florini Amalia Yellow’ | N/C | Reduced height & flower scent at 0.05 ppm ethylene |

| Tomato ‘Beefsteak’ | Epinasty within 24 hours of exposure to 0.01 or 0.05 ppm ethylene | Reduced overall growth & height |

| Torenia ‘Clown Blue’ | N/C | Reduced overall growth, height and flower counts |

| Verbena ‘Lannai Dark Red’ | Slight leaf curling 24 hours after exposure to 0.05 ppm ethylene | Reduced height |

Detecting ethylene

If you suspect ethylene is present, then the first thing to do is verify that there is indeed a problem. One of the easiest ways of detecting ethylene is by the use of indicator plants. These are plants so sensitive that they respond dramatically even at concentrations as low as 0.01 ppm. Cuphea and Tomato both make excellent indicator plants. Cuphea will abscise all its flowers (Figure 2); and tomato will bend its leaves downward as if they are wilted but they will remain turgid (epinasty) when ethylene is present even in very low concentrations. Such responses usually show up within 24 hours of exposure, though lower greenhouse temperatures can slow the response. Use indicator plants which have not previously been exposed to ethylene and place them throughout the greenhouse including any areas where you suspect ethylene is originating.

A second and more reliable method to detect ethylene is by sending an air sample to a commercial lab or a university lab such as the one at North Carolina State University Plant Disease and Insect Clinic. Contact the lab directly to find out about the details of the program, obtain the necessary instructions and materials for collecting an air sample before sending one in. When taking samples to send for testing, choose from areas where you suspect ethylene may be coming. These could be inside, near a unit heater, or outside of the greenhouse, near a loading dock. Also sample areas where there is no ethylene problem, as a basis for comparison. Commercial kits for detecting ethylene are also available, but are not sensitive enough to detect low concentrations.

A second and more reliable method to detect ethylene is by sending an air sample to a commercial lab or a university lab such as the one at North Carolina State University Plant Disease and Insect Clinic. Contact the lab directly to find out about the details of the program, obtain the necessary instructions and materials for collecting an air sample before sending one in. When taking samples to send for testing, choose from areas where you suspect ethylene may be coming. These could be inside, near a unit heater, or outside of the greenhouse, near a loading dock. Also sample areas where there is no ethylene problem, as a basis for comparison. Commercial kits for detecting ethylene are also available, but are not sensitive enough to detect low concentrations.

Finding the source

If you find that ethylene is present in your greenhouse, the next step is to find the source. Ethylene can come from several sources, such as ripening fruit, decomposing plant material, plant growth regulators that release ethylene, and as a by-product of incomplete combustion.

One class of plant growth regulators (including Florel© and Pistill©) works by producing low concentrations of ethylene when the active ingredient breaks down. If applied near or onto sensitive species, the same brief exposure, low concentration ethylene responses will be seen. Florel’s ethylene is largely dissipated within 72 hours.

The most common source of ethylene in a greenhouse is from combustion of fuel. Any type of combustion whether an engine or a heater, can give off ethylene. Loading docks near the greenhouse and heavy equipment used inside the greenhouse can both be sources. Avoid using gasoline or propane-powered equipment at times when the houses are not ventilated. Of course the most common type of combustion in the greenhouse is the heating system itself. A poorly operated or maintained heating system can rapidly ruin a crop.

Historically, as fuel prices increase, so do reports of ethylene damage. When fuel prices are low and greenhouses are not as tight or thoroughly insulated, ethylene from existing sources is easily ventilated away through leaks. But, when fuel is expensive growers tighten and insulate houses, and ethylene from pre-existing sources builds up and becomes a problem. So, ethylene that was not a problem before becomes a problem when fuel becomes dear and the greenhouse is tightened.

Preventing ethylene damage

If you discover that you do have an ethylene problem, the easiest and most immediate intervention is periodic ventilation of the greenhouse with clean outside air. Of course this is only a short term fix, and shouldn’t be considered a long term solution, particularly when heating costs are high.

The best approach to stop ethylene damage is the time honored ounce of prevention. Careful and regular attention to the plant growing environment, shipping areas and post-harvest conditions can go a long way. In any of these areas ethylene can be present. Be sure to keep the potential sources mentioned above away from highly sensitive crops. Pay special attention to when and where heavy equipment is used. If heavy equipment is used near the greenhouse, be sure that the house is well ventilated so that the exhaust can rapidly escape. Wherever possible, seal off the house from loading docks or similar areas. If growing areas cannot be sealed off from loading docks, consider using battery operated equipment whenever possible. When designing a new greenhouse, orient intake vents such that they face away from areas where vehicles frequently operate.

By far the most frequent source of ethylene is a malfunctioning heating system. Diligent heating system maintenance not only prevents ethylene problems but also improves your system’s efficiency. Of all the heating systems available, typically gas fired unit heaters require the most attention in terms of ethylene. Key issues with unit heaters are maintenance, distribution tubes, vent stacks, ventilation, and fuel lines. An annual maintenance program should start with the heat exchanger. Check the exchanger for cracks by operating the unit while looking for light through seams and connections. Gas lines should be checked for leaks by painting them with soapy water and looking for bubbles. Vent stacks should be examined for blockages or leaks between the seams. The stacks should be high enough so that there is no risk of exhaust making its way back into the greenhouse. The pilot light and orifice should also be inspected and cleaned. The furnace flame normally burns light blue, if it is orange or yellow combustion is incomplete and service is needed.

Outside of maintenance, the installation of gas fired unit heaters must be done carefully to avoid problems from a heater that is capable of operating perfectly well. A distribution tube should be installed to mix the hot air coming from the heater with ambient air and distribute it efficiently throughout the greenhouse. The mixing of hot air with ambient air dilutes any potential source of ethylene and eliminates temperature gradients. Distribution tubes are especially important for unvented heaters which release the products of combustion into the greenhouse. Unvented heaters are very popular when heating costs are high because of their efficiency. When unvented heaters are used it is critical to periodically check that they are firing correctly and that adequate ventilation of outside air is available.

Air intake required for combustion (make-up air) is also important for unit heaters. If the heater has an insufficient make-up air, oxygen levels within the greenhouse can drop and pollutants can build up quickly. Such a condition is not only dangerous to the crop but to personnel as well. Generally, 1 square inch of vent cross-sectional area per 2,000 Btu capacity is enough. You will find specific information in the installation and operation manual for your furnace.

The key to preventing ethylene damage is being proactive. Ensure that heaters and equipment are well maintained, and reduce plant exposure to potential ethylene sources. Keep an eye on your plants for irregular growth and if potential ethylene damage is suspected be ready to take steps to identify the source of the problem and eliminate the cause.

Links:

Ethylene: Sources, Symptoms and Prevention for Greenhouse crops – A detailed guide to identifying and solving problems with ethylene in production greenhouses.

North Carolina State University Plant Disease and Insect Clinic – The clinic offers ethylene testing at very low cost. You will need to contact the clinic directly to obtain details about the program, an ethylene sampling kit, and instructions on how to collect samples.

Heating Systems Maintenance Pays – A general guide to seasonal heating system maintenance for both oil and gas systems.

Avoiding Ethylene Problems. Runkle & Beudry. GPN 2006. Description of common ethylene problems, sources and sampling technique.

Print resources:

Ethylene: Agricultural Sources and Applications – Muhammad Arshad and William T. Frankenberger. A detailed description of biological activity, history, sources, applications, and biosynthesis. Additional chapters on application of ethephon/florel in agriculture.

Acknowledgements:

This work was funded, in part, by a grant from the Fred C. Gloeckner Foundation, Inc. Plant material was donated by C. Raker and Sons, Inc. We also acknowledge the valuable cooperation of numerous New York growers for sharing their insights on their own ethylene experiences.